My Brompton needed a new front wheel, so I thought I’d replace it with one with a dynamo hub. I’d built one of these for my “normal” bicycle and liked the battery-free endless light power it provided.

Brompton can provide you with such a wheel, albeit at some cost. There is a Shimano-based one, which has just been discontinued. Or one based on the expensive but much-admired SON hub. This one is currently on model changeover.

The latest version of the SON Brompton hub uses 20 straight-pull spokes and weighs a little less than the original 28-spoke version, which in turn weighed a little less than the Shimano one.

The “old” SON was available, the new one on back order.

Note to self: best not try to buy dynamo hubs at the onset of winter.

Hence I bought a not-much-discussed Brompton-specific dynamo hub made by Shutter Precision:

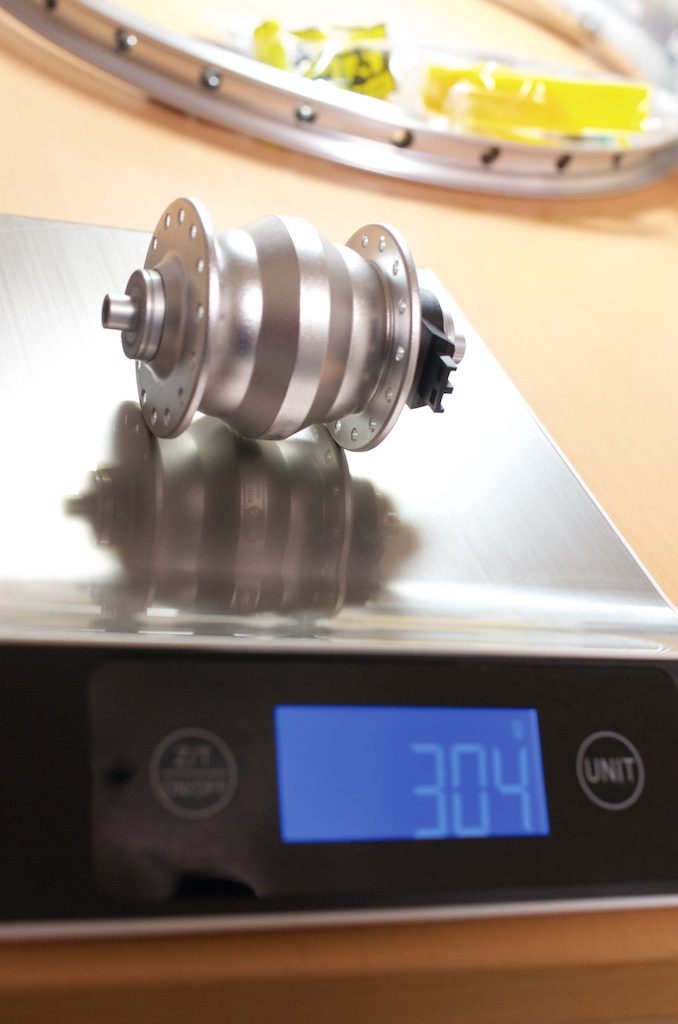

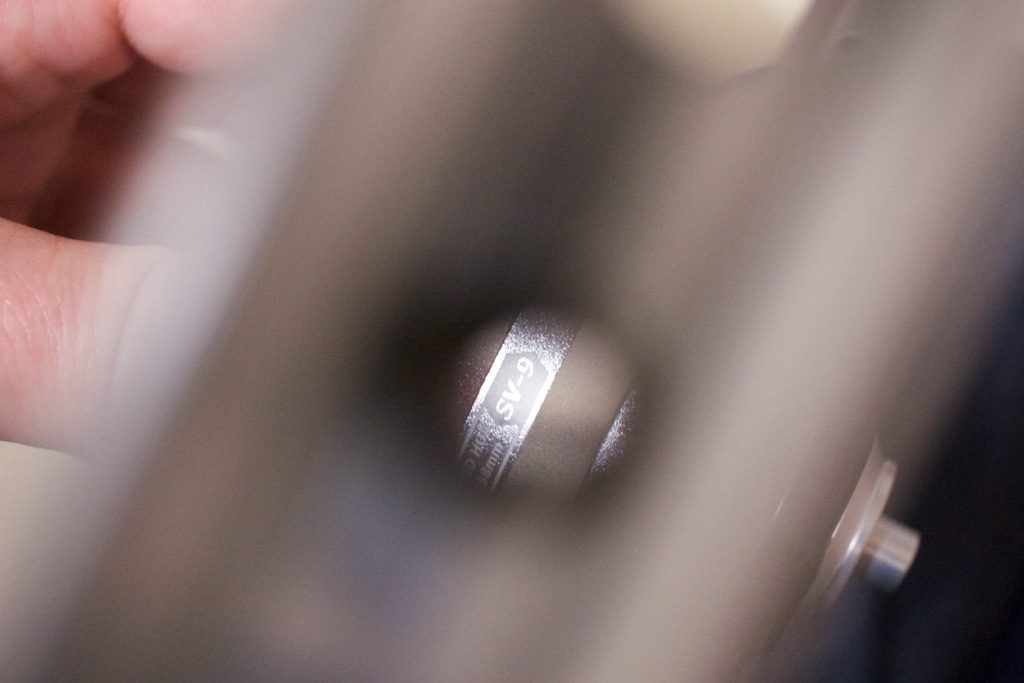

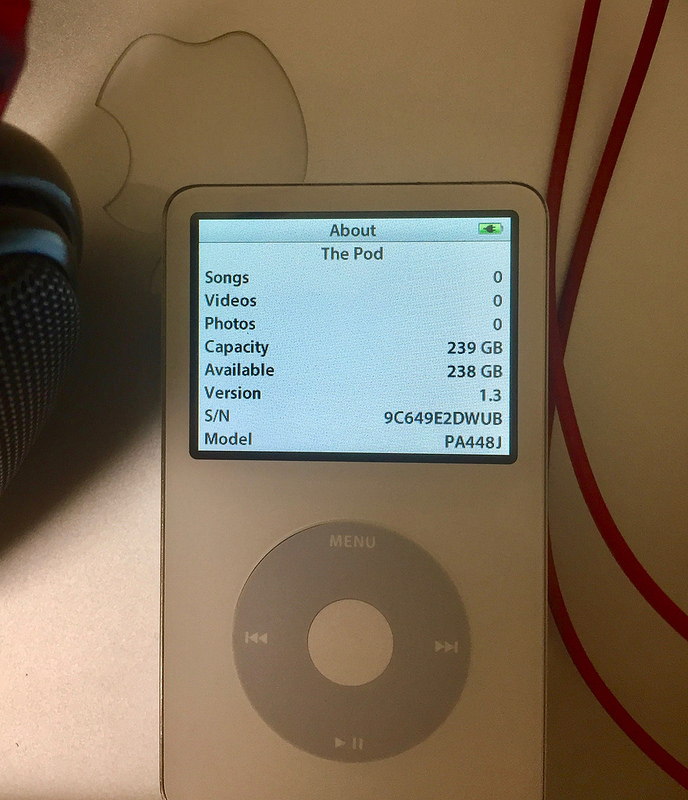

Behold, the 304 gram Shutter Precision SV-9-FB SL. (Manufacturer’s claimed weight: 299g)

That’s very light for a dynamo hub. It’s tiny, too. The central bit about the size of a golf ball:

The “SL” in the name denotes silver. It is also available in black. While we’re decoding the model, the B denotes Brompton, compatible with the slightly thinner axles Brompton use. A non “B” one is also available, for other folding bikes with standard diameter skewers.

The SV-9 is the latest series from Shutter Precision, a company based in Taiwan, the world’s centre of bicycle and parts manufacturing. This model is for modern LED lights, super-efficient, and very low drag.

Note that this particular hub fits 74mm wide “over lock dimension” forks common to folding bicycles only. Most non-folding bicycles are 100mm or more, and you’ll need a different hub for those.

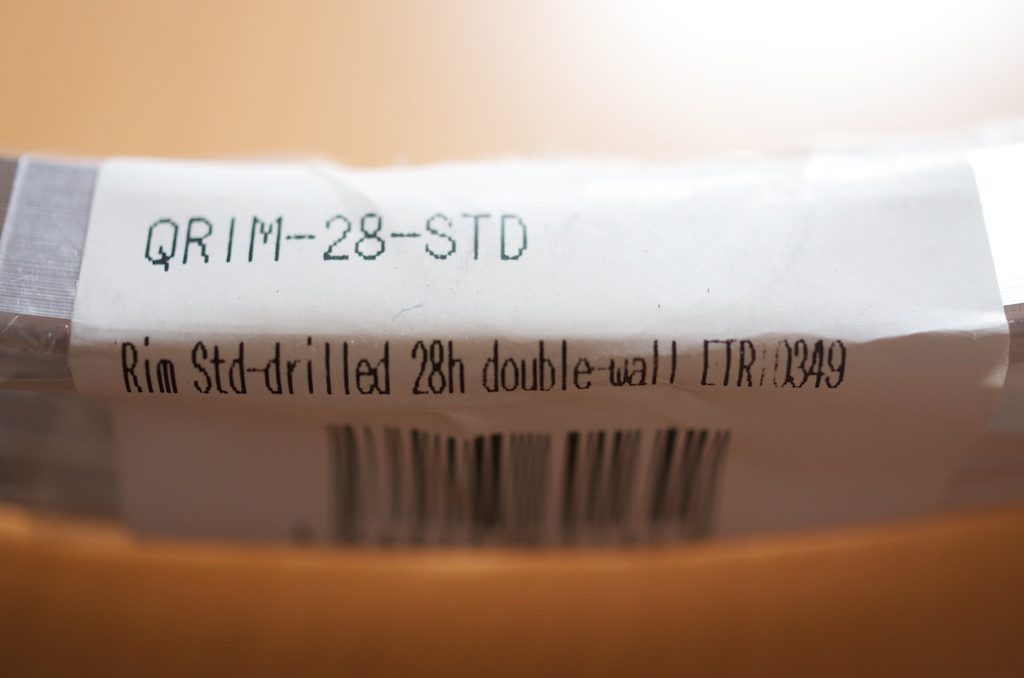

I also bought the standard Brompton front wheel rim:

As it says on the label: 28-hole, double-walled, with bead seat diameter of 349mm. This is the one recommended by Brompton for front wheels, including those with dynamo hubs.

Brompton also do the same rim with the holes drilled at a more aggressive angle to suit rear wheels with internal geared hubs, so choose rim and hub carefully.

Here are the other components on the scales, for those interested. 28 brass nipples come in at 25g:

28 2mm straight-gauge spokes at just 107g…

And that rim, at 317g:

This all adds up to a total (measured) weight of around 750g. The 20-spoke SON, for comparison, weighs 730g (manufacturer figures).

You could build this wheel a little lighter using aluminium nipples instead of brass and butted 2mm/1.8mm spokes instead of sturdy 2mm straight gauge ones. But 750g is a very light dynamo wheel, and with 28 x 2mm spokes, very strong too.

So to building…

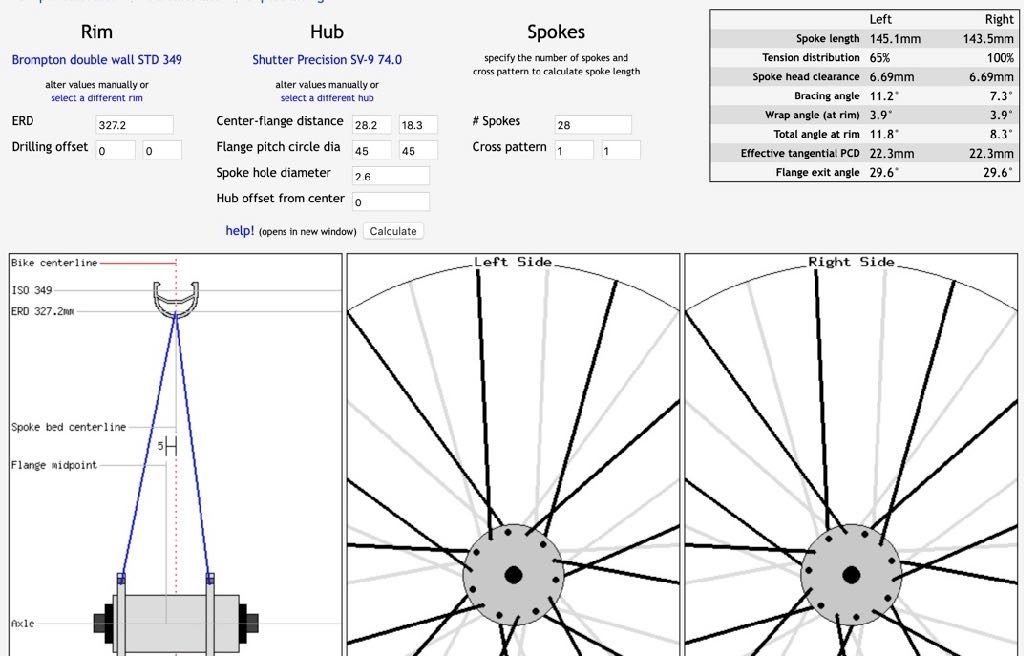

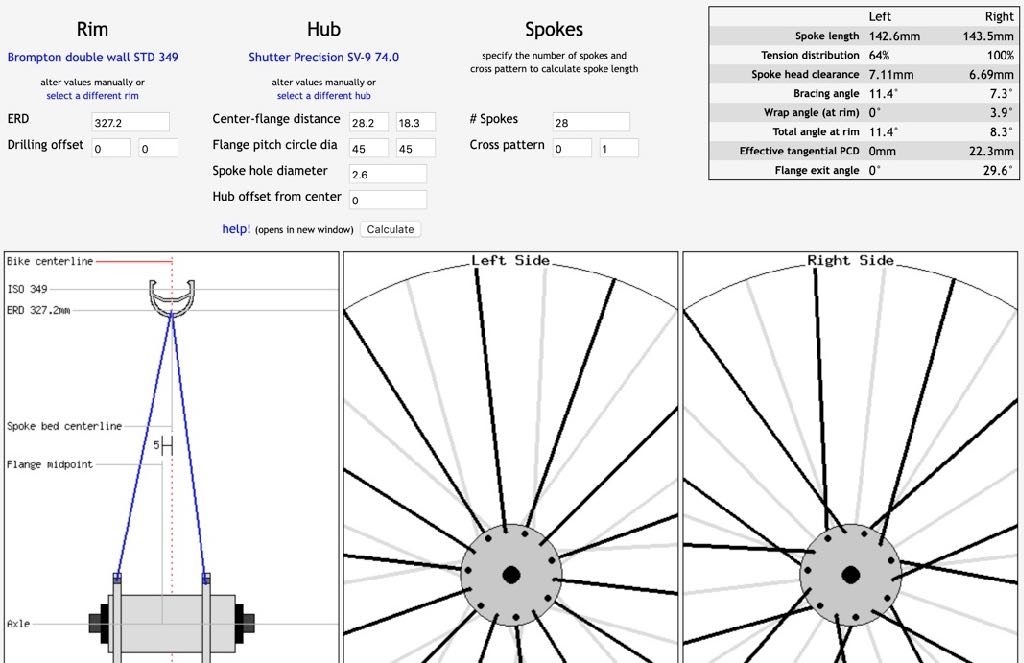

The required spoke length depends on the effective rim diameter, hub dimensions, and lacing choice. Brompton recommend 1-cross lacing for these rims, including with dynamo hubs.

The existing wheel (the original “super light” wheel, fitted as standard to my titanium Brompton) used an older single-wall rim, and was radially laced.

More on that later.

Various spoke length calculators were consulted and the dimensions of rim and hub entered. Note that this hub has offset flanges – the right flange is closer to the centre of the hub to make room for the dynamo power output tab.

This means that, like a rear freehub wheel, you will make a dished wheel. The spokes on the right hand side will be shorter:

Here we can see that for 1-cross, the left hand spokes should be 145.1mm and the right hand side spokes 143.5mm.

Now I couldn’t find these exact lengths readily available, unlike for standard-sized wheels. And I didn’t know of a local place that would cut custom length spokes.

But I had a plan…

Brompton sell 145mm spokes for their own wheels. I bought a set of these. You get 29 in a packet, and 29 brass spoke nipples. So one spare of each for this 28 hole wheel.

But aren’t these too long? Yes, the danger being that to sufficiently tension them, the spoke nipple would have to be wound down too far into the spoke, and may run out of thread to bite in to, the spoke passing beyond the head of the nipple.

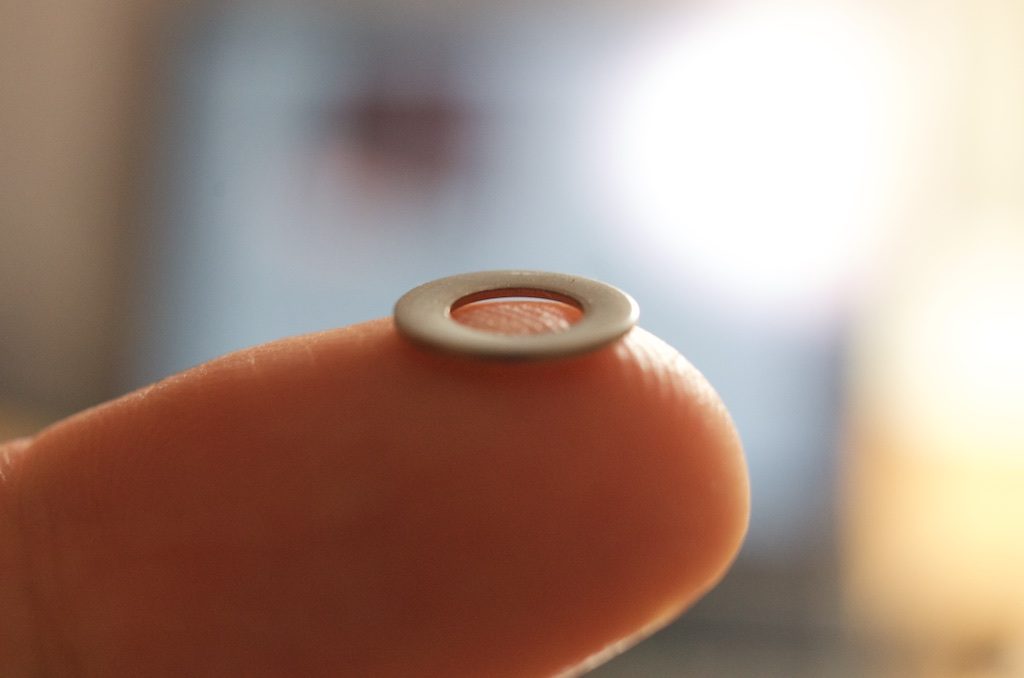

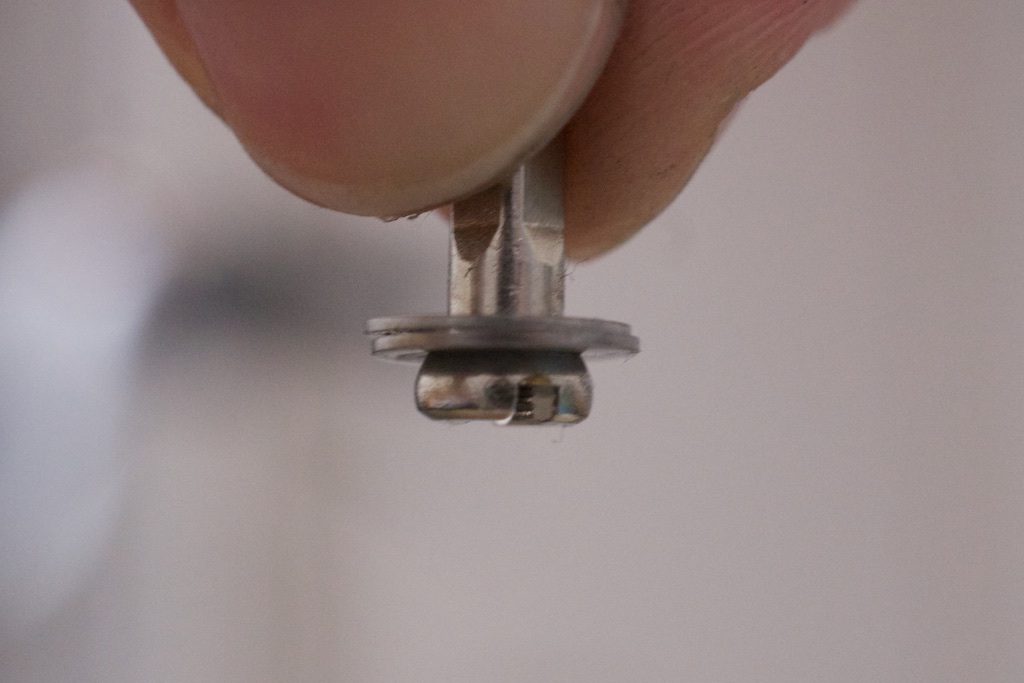

The solution, which only really works for double-walled rims, is to fit these nipple washers:

I used Sapim washers, which are about 0.7mm thick. These stop the spoke nipples from being wound too far onto the spoke. The small difference (143.5mm vs 145mm) in spoke lengths is easily compensated.

Here’s the full set of parts ready to be built:

Before beginning, I noticed the rim was very roughly machined around the spoke holes:

There were even bits of metal swarf from this machining rattling around inside the hub.

I cleaned it all up. This is probably the worst finishing I have seen on a new rim. Fortunately, the nipple washers will help to mitigate the impact.

I begin by greasing the spoke holes…

And a little on the spoke thread:

Then begin to lace up, remembering to use a nipple washer on the “too long” right-hand-side spokes:

As ever, I follow Sheldon Brown’s wheel building guide.

There are other techniques, but this guide has worked for me before. The only thing I can think to add is that every sentence in the part about lacing is meaningful.

If you get to a point where you think “my wheel doesn’t look like that”, or “that sentence seems to be irrelevant…” you are most likely about to make a mistake.

Go slowly and it will all be fine.

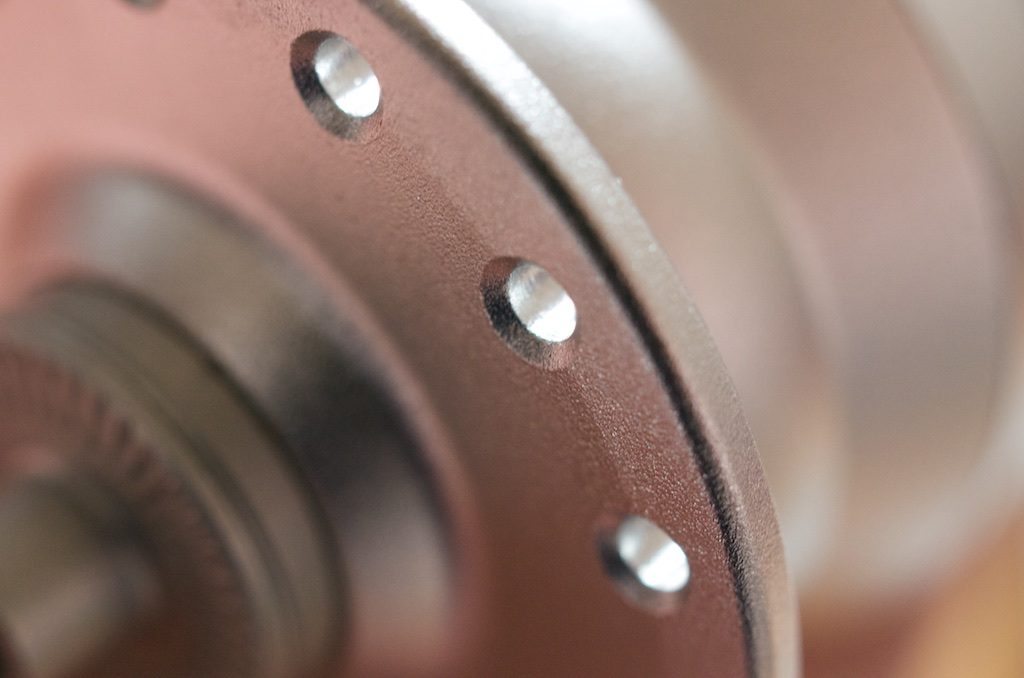

The hub I have has no particular handedness for the drilling, all holes are chamfered on both sides:

But the rim holes were slightly angled left and right, so take care to lace to the correct ones. As planned, I laced it 1-cross. As suggested by Sheldon, I made sure the hub label was visible through the valve-hole.

A sign of the careful builder:

The spokes went in smoothly. Shown here loosely assembled before tensioning:

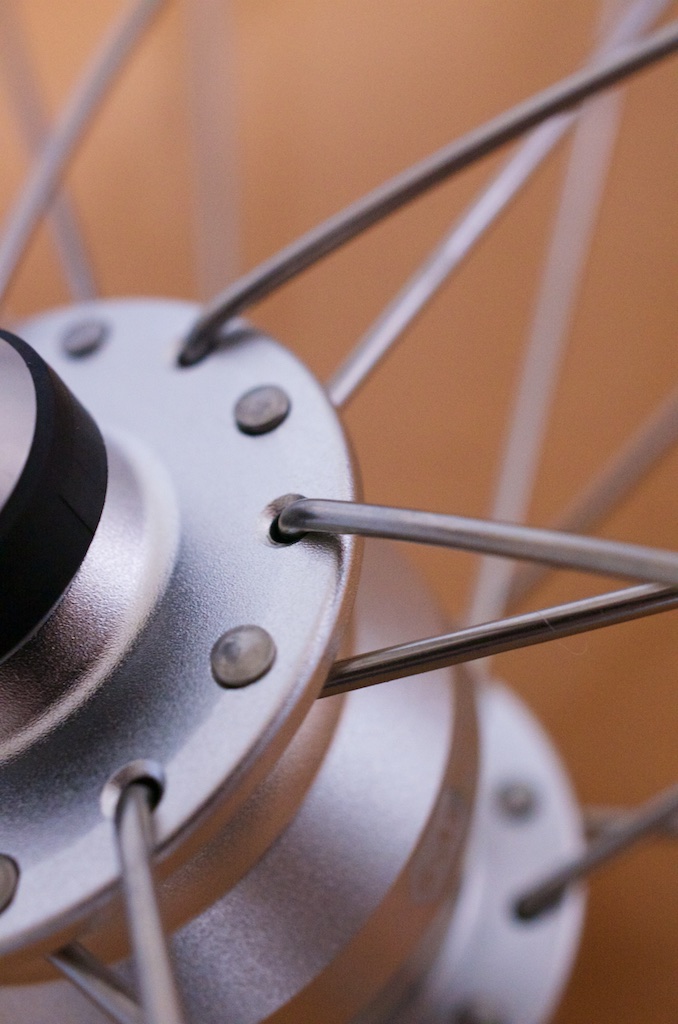

Now one thing had concerned me, alluded to earlier. The original wheel was radially laced (“0-cross”) and all the spoke heads were on the outside of the hub, the spokes exiting the flange on the inside.

You can see it here in this picture of the old wheel (loosened for removal):

With the Shutter Precision dynohub having the left hand flange so close to the end of the axle, would there be a problem with the spokes exiting the flange on the outside?

Measurements suggested it would be very close.

To solve it, I fitted the un-tensioned new wheel…

And well, see for yourself:

Now those outside spokes would straighten up under tension (I tried one or two to check) and would just clear the inside of the fork. But tolerances were minute, and a lightly bent spoke would create a problem. Not acceptable.

Note that the Shimano and SON dynohub flanges are both further inboard, and don’t have this issue. Perhaps that’s why people use them.

I decided to see how short the spokes would need to be should I radially lace the left hand side, with all the spokes exiting on the inside of the flange to create clearance – just like the original super light wheel.

As below, note “Cross pattern” 0 and 1 are entered in to the spoke calculator…

Left hand spokes in this case would need to be 142.6mm! Quite a bit shorter than my 145mm lengths.

The solution was already at hand… two of the Sapim nipple washers:

Using two washers on the left hand side spokes, and retaining the right hand side 1-cross laced (with one washer per spoke), I completed the wheel.

With the washer(s) fitted, you can see that the spoke thread enters the head of the nipple, but not beyond it. There is still a little tension to be added here:

This also shows why you need double-walled rims, otherwise the nipple head would be pushing into the tube. It also shows again the poor finishing of the Brompton drilling. You’ll never see this if you buy a wheel with rim tape already fitted, of course.

Here is the left hand side, now radially laced with the spokes exiting from inside the flange:

And the right hand side, 1-cross laced:

The wheel was tensioned, stress-relieved and trued. Finally, the rims were cleaned again and the rim tape added:

Tip: The Brompton tyre remover (or any flat non-sharp blade) is useful in centring the rim tape, which inevitably attempts to seat itself to one side or other. Use the yellow rim tape on the double-walled rims. The single-wall rims need the blue tape.

I fitted the wheel to the Brompton and checked the brake clearances:

Clearance near the fork ends was now more than fine too, and the wheel spun well.

I replaced the original battery lights with a B&M IQ-XS front light, and Brompton dynamo rear light:

B&M IQ-XS front light, fitted to the Brompton extended front light hangar:

Both are very bright and are fitted with standlights, staying powered for a few minutes after the wheel stops turning:

That’s it.

Thanks for posting! Really useful! Brompton clearances are nuts

Thanks for your comment, glad you appreciated the post. (The bicycle was stolen sometime after I added this wheel – I hope the thief appreciates my efforts as much 😩)

Er, weird. Did they change the design of the offsets on the SP hubs? I built a SV8 Brompton dynamo wheel in 2020 lockdown and didn’t have to account for any offset, just checked my wheel and the specs on the SP website and the locknut points and flanges are both equidistant from centre and your flange looks way slimmer on the non-connector side unless I’m missing something, this also means I had no clearance concerns at all.

David, many thanks for your comment and update on the current SP design. Perhaps they read this post too?

[…] and production issues related to the pandemic. This was almost an emergency purchase, as my Brompton had been stolen, and my remaining daily steed had experienced something of an […]